Frequently asked questions.

Frequently asked questions.

Operating since 2014, we have developed an expertise that offers unparalleled quality and service.

The machine operates by aligning and separating fibers, cleaning impurities, and forming a thin web. It typically involves a series of rollers and wire-covered cylinders that perform the carding process.

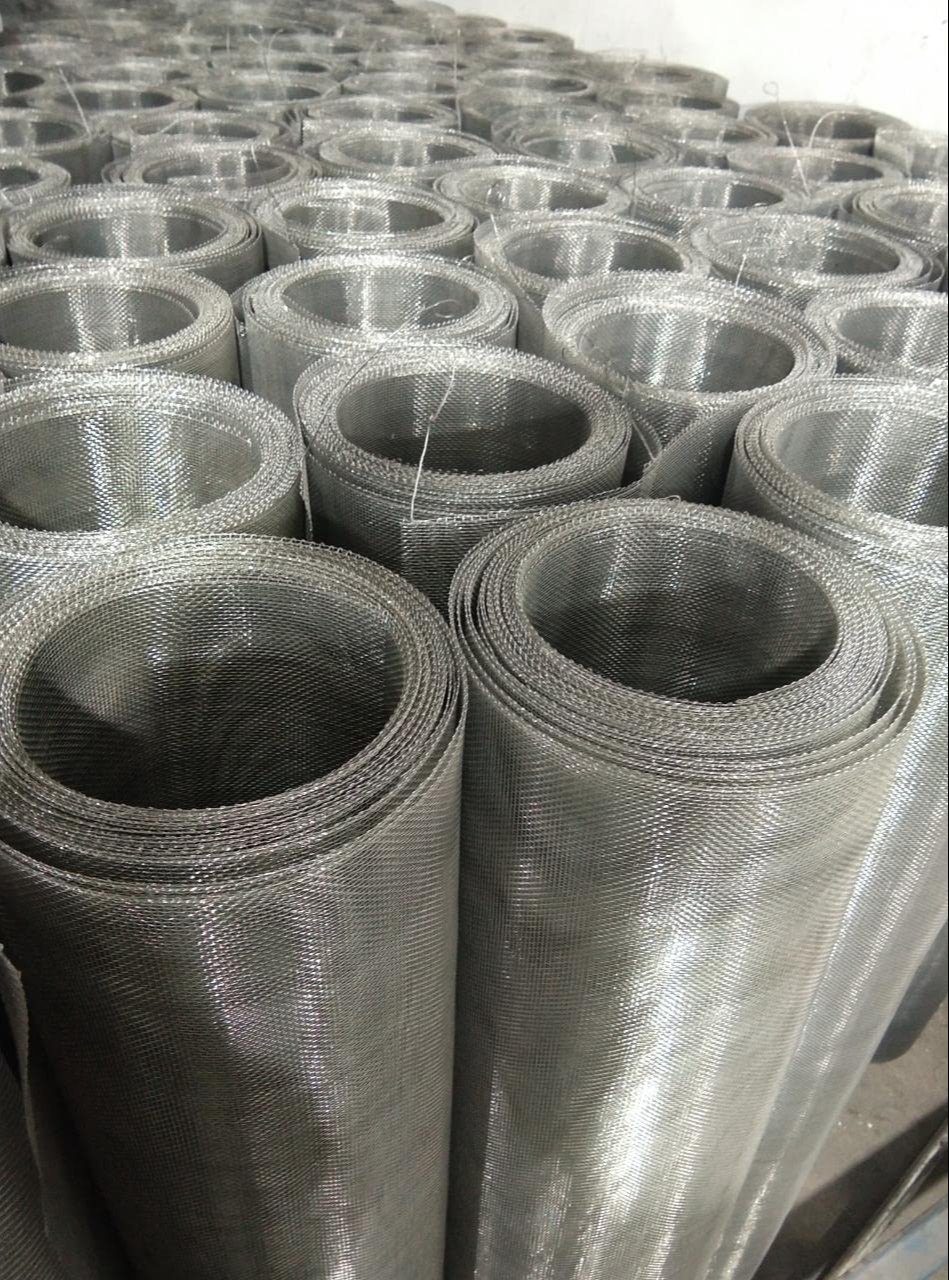

Wire mesh is typically manufactured through processes such as weaving (for woven mesh), welding (for welded mesh), or expanding and perforating (for expanded and perforated mesh). These processes may involve using automated machinery to ensure precision and consistency.

Yes, many wire mesh factories offer customization services. Customers can request specific dimensions, materials, mesh configurations, and finishes based on their unique project requirements.

Carding is a critical step in the textile manufacturing process as it aligns and parallelizes fibers, removes impurities, and creates a uniform web or sliver. This prepared material is then ready for further processing in spinning mills.

Quality control measures may include regular inspections, testing of raw materials, dimensional checks, and adherence to industry standards. Some factories may have certifications indicating compliance with quality management systems.

Regular maintenance involves cleaning the machine, checking wire points for wear, inspecting belts, and ensuring proper lubrication. Maintenance schedules may vary based on usage and manufacturer recommendations.